Edmonton, AB – 2024-08-26 – Wenzel Downhole Tools (WZL) is pleased to add tungsten carbide tiling to their extensive catalogue of in-house manufacturing capabilities.

Tiling is a popular upgrade option on all new drilling motor flow restrictors, and the ability to offer this service in-house will help further control flow of production, and ensure customers receive high-quality products as efficiently as possible.

What is tungsten carbide tiling, and how is it applied?

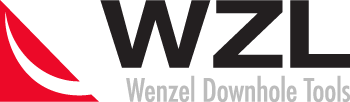

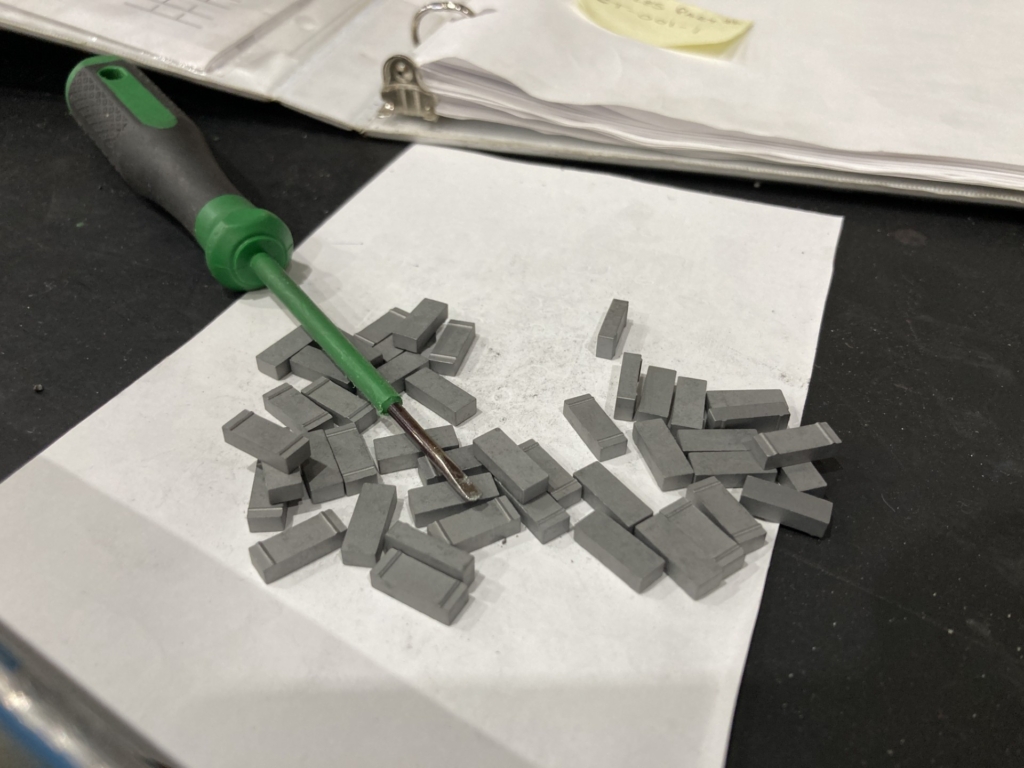

Tiling is applied entirely in-house through an advanced manufacturing process that entails welding individual tungsten carbide tiles before cementing the inner and outer tile walls with a robotic plasma transferred arc (PTA) application of tungsten alloy. The walls are then ground to leave a smooth, incredibly hard and durable low-friction surface (see photos below).

Adding carbide tiles to a design that is already considered industry-leading further enhances the world-class quality of this high-value, heavily abused component. Bringing the process in-house under the watchful eye of WZL Manufacturing makes it all even better.

Benefits of carbide tiling in flow restrictors

- Enhanced durability: Incorporating hard, wear-resistant tungsten carbide tiles can significantly increase a flow restrictor’s lifespan. The material stands up exceptionally well to downhole abrasives and generates less heat thanks to its low-friction properties.

- Improved performance: By resisting wear, WZL flow restrictors can maintain consistent and predictable pressure and performance, giving operators the precise flow and control they need for an efficient run.

- Cost-effectiveness: The durability and performance benefits of high-quality carbide reinforced components reduces the need for frequent replacements and minimizes unexpected downtime.

WZL has already seen the benefits of overseeing the tiling process in-house. Jordan James, VP, Engineering has noticed that “ensuring the combination of hardness, carbide content, and bond strength in both the tiles and matrix has improved wear life and improved part reliability.”

While estimates will always depend upon drilling conditions and operator handling, new WZL flow restrictors completed under our could provide up to 500 hours of life and allow operators to drill further and longer than ever before.

Order your WZL drilling motors and flow restrictors

WZL flow restrictors are available on all new WZL drilling motors and can also be purchased individually to enhance existing inventory.